The team is composed of young professionals with a strong aptitude for collaboration, united by the brilliant academic curriculum in various disciplinary sectors, both technical and scientific, including: research doctors; control, vehicle and mechanical engineers; mathematicians and doctors in economics and marketing.

The high level of training, interdisciplinary skills, the effective methodological approach and the experience gained in industrial relations are the strengths of the Pure Power Control team.

A work team united by the passion for technological evolution, by the tension to results and rigor in the conception and implementation of solutions, always attentive to customer needs.

A reality that stands out for its ability to decline the progress of basic research and applied research in the industrial application, reworking the results of greater impact for the conception, development and implementation of products with high innovative content.

Our skills

Pure Power Control adopts state-of-the-art methodologies and tools in the development and management of its projects such as: six sigma, design for six sigma, axiomatic, model-based system engineering, model-based design.

Design For Six Sigma (DFSS) can be seen as a theory that links different areas of knowledge that are not necessarily engineering and that aspires to develop projects for new processes or products that are optimal in terms of the full satisfaction of the final customer’s requirements.

The term “Six Sigma”, just as it is reflected in the well-known Lean Six Sigma methodology in the improvement of existing processes and products, in the context of the DFSS is defined as the level at which so-called conceptual or operational product vulnerabilities also called Critical to Quality or Critical to Satisfaction (CTQ or CTS) are minimized at project level.

The DFSS in particular is based on particular project methodologies, such as Axiomatic Design and Theory for the Inventive Solution of Problems (commonly identified with TRIZ), and on a broad spectrum of quantitative statistical tools (e.g. Hypothesis Testing) or qualitative (e.g. DFMEA) that allow, starting from evaluations also in the form of empirical measures and assessments on the field of customer requests (VOC, Voice Of the Customer) and prototypes or process or product simulations through approaches such as Design Of Experiment (DOE) or the Taguchi Method, to realize specimens that show to be “correctly designed immediately” (“design it right the first time”) making scarce the chances of returning to them after the relative production. It is therefore clear the purely “proactive” approach of the DFSS against the “reactive” approach (firefighting) not methodologically structured in the design.

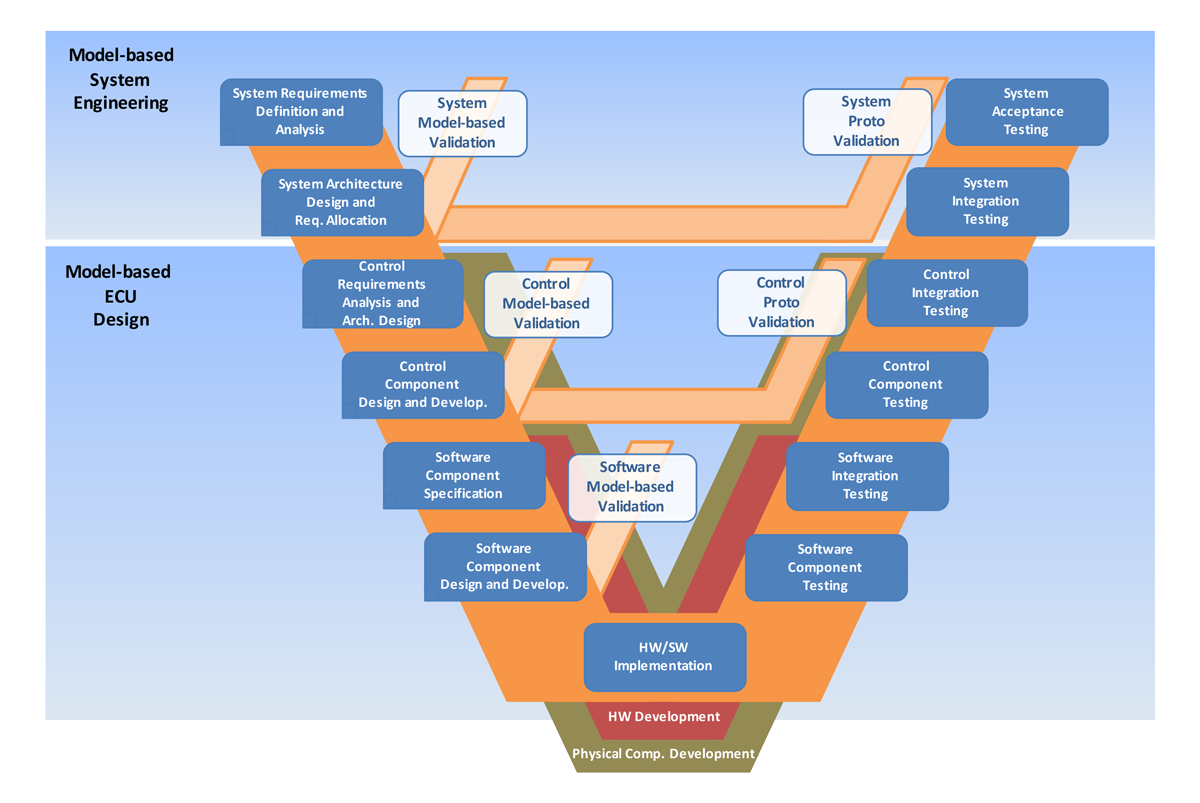

Model-based design is a mathematical methodology with graphical support used to resolve problems related to the design of complex control systems. It is applied in many fields: the automotive industry, aerospace, and in particular in the design of embedded software. It consists of the formalized application of modeling to support the entire process of product development: formalization of requirements, system design, analysis, verification and validation of the integrated system. The model-based design allows a reduction of time and costs thanks to the reduction of design time, avoids re-design, and is optimized and validated for the design and development of mechanical, hydraulic and embedded control systems.